FLYING LESSONS uses recent mishap reports to consider what might have contributed to accidents, so you can make better decisions if you face similar circumstances. In most cases design characteristics of a specific airplane have little direct bearing on the possible causes of aircraft accidents—but knowing how your airplane’s systems respond can make the difference in your success as the scenario unfolds. So apply these FLYING LESSONS to the specific airplane you fly. Verify all technical information before applying it to your aircraft or operation, with manufacturers’ data and recommendations taking precedence. You are pilot in command and are ultimately responsible for the decisions you make.

FLYING LESSONS is an independent product of MASTERY FLIGHT TRAINING, INC.

Pursue Mastery of Flight™

This week’s LESSONS:

Thank you to my friends and hosts at last week’s Australian Beechcraft Society biennial training conference at Cowra, New South Wales—my seventh live presentation Down Under, dating back 22 years—and the dozens of Aussie Beech pilots who attended. Continuing my focus on the outstanding work of the Australian Transport Safety Bureau (ATSB), here is another LESSON inspired by an ATSB investigative report.

Thank you to my friends and hosts at last week’s Australian Beechcraft Society biennial training conference at Cowra, New South Wales—my seventh live presentation Down Under, dating back 22 years—and the dozens of Aussie Beech pilots who attended. Continuing my focus on the outstanding work of the Australian Transport Safety Bureau (ATSB), here is another LESSON inspired by an ATSB investigative report.

What happened

On the morning of 19 December 2021, a Rockwell Commander 114…departed Redcliffe aircraft landing area, Queensland for a private flight. On board were a pilot and 3 passengers. Shortly after take-off, the engine lost power and the pilot elected to return to the airfield. During the return, the aircraft lost altitude and impacted the ocean before becoming inverted. The occupants were unable to escape the aircraft and were fatally injured, and the aircraft was destroyed.

What the ATSB found

The ATSB found that during preparation for the flight, a perceived engine problem distracted the pilot during the conduct of pre-take-off checks. After rectifying the issue, the pilot did not complete the remaining pre-take-off checks (including fuel tank selection) before departure. Before take-off when there was no time pressure (and during the inflight emergency when there was), checks and action items were only done by memory rather than using the pilot operating handbook or third‑party checklists also on board.

While stored in the hangar, most of the fuel moved into the right wing tank. The pilot would have been aware of the fuel imbalance from measuring fuel in both tanks via a dipstick before flight. However, it was likely that the fuel tank selection prior to take-off was to the left fuel tank only, which led to fuel starvation and engine stoppage soon after take-off.

The pilot, likely experiencing the effects of stress and time pressure following the engine power reduction and then stoppage, did not conduct initial emergency actions and attempted to return to the runway for landing. However, the pilot did not maintain glide speed, and the aircraft impacted shallow water prior to reaching the airfield. During the return to the airfield, the pilot had extended the undercarriage for the intended landing. This contributed to the aircraft inverting when it collided with water. This likely resulted in occupant disorientation and added difficulty in operating the exits, reducing their ability to escape.

It is very likely that the passengers did not receive information about the brace position or actions to be taken in the event of a ditching as part of the pre-flight briefing. In the limited time available inflight after the power loss, the pilot also did not provide an emergency briefing or any instructions to passengers prior to impact with the water.

While the pilot was primarily responsible for the operation of the aircraft exits in an emergency, seating a child, who may require assistance, adjacent to an exit instead of an adult meant that a less suitable passenger was available to operate the exit.

Safety message

Use of the approved aircraft checklists, taken from the pilot operating handbook, provides pilots with the appropriate checks to be conducted for the aircraft type. Having these readily available in a written form, for the preparation and conduct of a flight, provides pilots with the detailed normal and emergency checks specific to the aircraft type without having to rely on committing these to memory. This ensures that aircraft are operated in a way that meets aircraft flight manual requirements and limitations.

Distraction can impact proper procedural processes and lead to interruption and omission of safety critical elements before take-off. The habit of restarting an interrupted checklist from the beginning is a means of ensuring that all steps to be performed are done so in order and the checklist is complete.

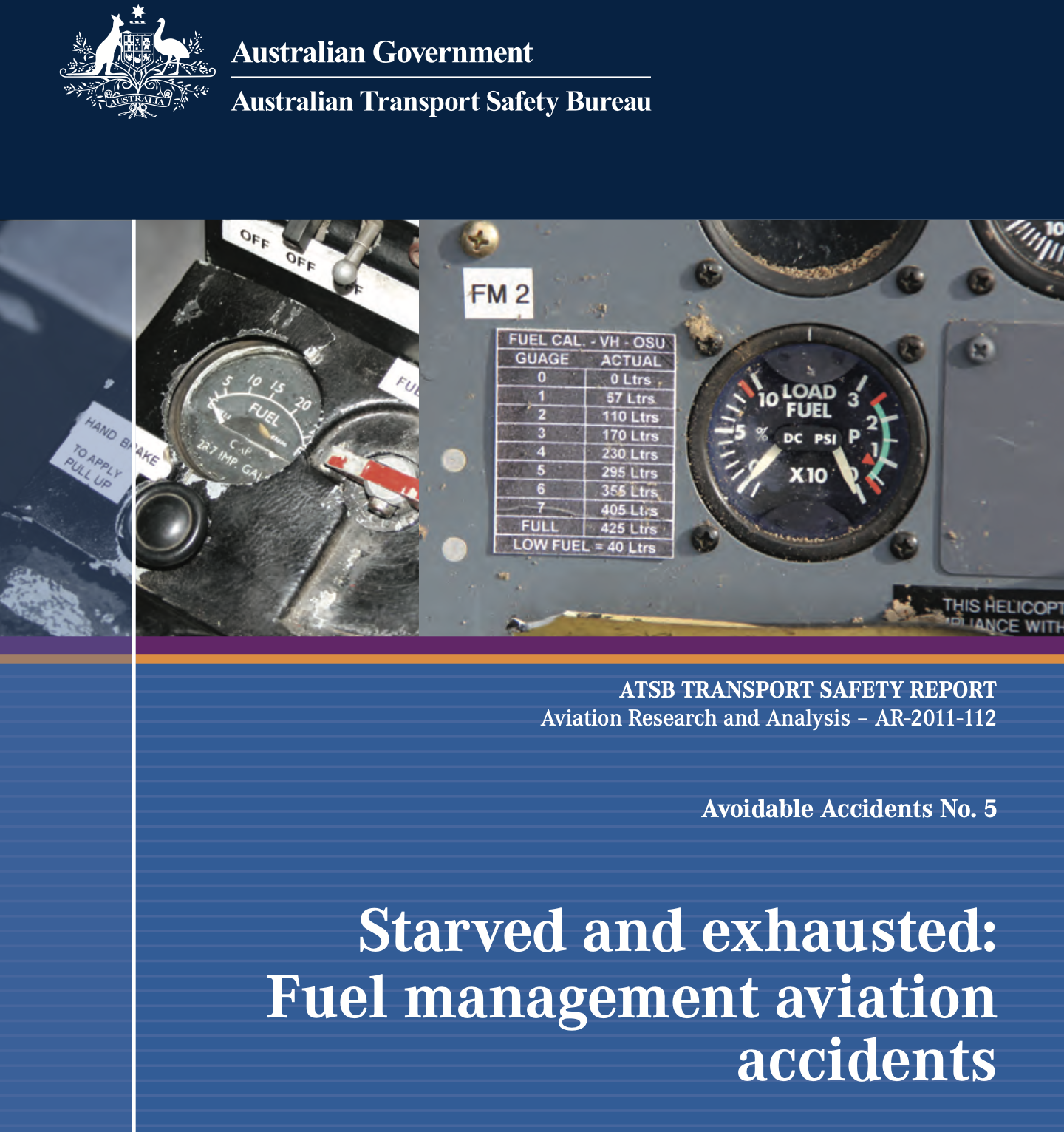

Proper fuel management will ensure fuel supply to the engine(s) remains uninterrupted at all stages of flight. The ATSB publication, Avoidable Accidents No. 5 – Starved and exhausted: Fuel management aviation accidents (AR-2011-112) outlines strategies and key messages for fuel management.

Proper fuel management will ensure fuel supply to the engine(s) remains uninterrupted at all stages of flight. The ATSB publication, Avoidable Accidents No. 5 – Starved and exhausted: Fuel management aviation accidents (AR-2011-112) outlines strategies and key messages for fuel management.

Thorough pre-flight briefings of passengers on how to operate exits, the brace position and actions that might be required in a ditching or other forced landing are essential to increase post‑impact survivability. Additionally, as supported by guidance, pilots should consider who might be best to assist in the case of an emergency, and brief and seat them accordingly.

Many years ago I was employed as safety director for a 400-employee company in the southeastern U.S. One of my many duties was management of two Beech Barons used for company transportation; I generally flew one (a 58TC) and the company president flew the other (a B55) when on visits to the company’s various work sites across a five-state area.

It was not unusual, however, for some reason for me to use the B55 and my employer to fly the larger, turbocharged Baron. Our standard procedure was to top off the fuel in the B55 (136 usable U.S. gallons) and the main tanks in the 58TC (166 usable) when returning home, since we tended to have very early departures on days we used the aircraft. The 58TC in particular has a very high useful load that made this feasible even if we had to carry some passengers and equipment.

But sometimes we planned a very heavy load, or returned very late, or for some other reason did not fuel up before putting the airplane in its hangar after a trip. If such an event combined with a pilot-swap, i.e., I was to fly the B55 or my boss the 58TC, it was vital we were able to positively determine the amount of fuel on board before making a flight—especially if the load on that flight prevented us from simply topping it off.

We had several ways to determine the amount of fuel on board. Each airplane had:

- A fuel totalizer that accurately measured the total fuel flow for both engines combined.

- Cockpit fuel gauges indicating the fuel level in each wing’s tank system.

- A written record we kept in the airplane, indicating the date, tachometer time and amount of fuel added when we refueled.

- Sometimes, a copy of a fuel receipt showing date and amount of the most recent fuel servicing.

Note that totalizers are only as good as the information you put into them. Beyond that, they detect fuel flow to the engine, but not where the fuel came from—if you’re flying an airplane with individually selectable tanks, like the Rockwell Commander in the ATSB report, it doesn’t protect against fuel starvation because it gives no indication of where on board the remaining fuel is stored.

Fuel gauges have a reputation for being inaccurate…but that’s only if the aircraft owner does not maintain them properly. You’ll often see online statements that fuel gauges are only required to read accurately when the tank is empty…but that’s only a partial reading of the regulation, the part where gauges must read zero when there is nothing but unusable fuel in the tank. It conveniently omits the additional requirement for the gauge to read accurately at each graduation marked on the gauge, i.e., one-quarter tank, half tank, three-quarters and full, etc.

If you have any doubts, look at the cover of the ATSB report pictured above. Australian aircraft owners are required to have their fuel systems calibrated every three years and a placard installed on the panel adjacent to the gauges to show the actual fuel level (in liters) for each marking on the gauge. This tells us it is possible to maintain factory fuel indicating systems to a level they indicate accurately—or predictably close to accurate—across their entire indicating range.

For more proof, the company-owned A36 Bonanza I fly has a five-year-old Garmin Engine Indicating System (EIS) with an integral fuel totalizer that reads accurately within one-tenth of a gallon, and the combined total matches exactly with the fuel gauges on the Garmin multifunction display…which are driven by the original Beech factory float transmitters that were installed when the airplane was new in 1981. No excuses: it is possible to have accurate cockpit fuel gauges.

Back to our Barons: The 58TC also has fuel level sight gauges in the top of each wing near the engine nacelle. These float-driven needles are accurate within a range of partial fuel levels. Notably, the shallow fuel bladder depth (about four inches) and wing dihedral of Barons, which necessitates placing the fuel caps at the outer end of the fuel tanks, means that with anything less than about three-quarters full tanks no fuel is visible through the fuel filler ports—all your see is the bottom of the tank. In an aircraft with wing dihedral and shallow fuel tanks “dip-sticking” the fuel level only works when the tanks are nearly full.

This multitude of ways to check the fuel level gave us a standard operating procedure (SOP) to help when the tanks of the Baron were not full and the pilot was not the same one who had most recently flown the airplane, and therefore did not have direct knowledge of the current fuel state.

The SOP was simple: Check all the available ways to determine fuel level—totalizer, fuel gauges, fuel record in the cockpit, fuel receipts if we had them, and the fuel sight gauges on the top of the 58TC’s wings. All these means of checking fuel level should be in agreement. If any one indicating method disagreed with the others the only correct action was to add fuel until the fuel level was visible in the fuel filler ports, or the amount of fuel added was itself enough to complete the upcoming flight with adequate reserves.

There are several other LESSONS to be learned from ATSB’s report on this tragic Rockwell Commander crash—distraction, preflight inspection, checklist use, passenger briefing, emergency procedures, attempting to return after engine failure, emergency egress and more. I hope you’ll re-read the report and think about your responsibility and proficiency in those areas as well.

But if you take only one thing away from this week’s Mastery of Flight, make a list of all the ways you can determine the amount for fuel on board your aircraft. Don’t take off if any one indicating method disagrees noticeably from the others.Resolve the discrepancy by adding fuel until you can positively determine there’s enough on board for your flight. Make that your SOP.

Questions? Comments? Supportable opinions? Let us know at [email protected].

Please help cover the ongoing costs of providing FLYING LESSONS through this secure PayPal donations link. Or send a check made out to Mastery Flight Training, Inc. at 247 Tiffany Street, Rose Hill, Kansas USA 67133. Thank you, generous supporters.

Thank you to our regular monthly financial contributors:

Steven Bernstein, Montclair, NJ. Robert Carhart, Jr., Odentown, MD. Randy Carmichael, Kissimmee, FL. Greg Cohen, Gaithersburg, MD. John Collins, Martinsburg, WV. Paul Damiano, Port Orange, FL. Dan Drew. Rob Finfrock, Rio Rancho, NM. Norman Gallagher. Bill Griffith, Indianapolis, IN. Steven Hefner, Corinth, MS; Ellen Herr, Ft Myers, FL. Erik Hoel, Redlands, CA. Ron Horton. Robert Hoffman, Sanders, KY. David Karalunas, Anchorage, AK. Steve Kelly, Appleton, WI. Karl Kleiderer. Greg Long, Johnston, IA. Rick Lugash, Los Angeles, CA. Richard McCraw, Hinesburg, VT. David Ovad, Resiertown, MD. Steven Oxholm, Portsmouth, NH. Brian Schiff, Keller, TX. Paul Sergeant, Allen, TX. Ed Stack, Prospect Heights, IL; Paul Uhlig, Wichita, KS. Richard Whitney, Warrenton, VA. Jim Preston, Alexandria, VA. Johannes Ascherl, Munich, Germany. Bruce Dickerson, Asheville, NC. Edmund Braly, Norman, OK. Steven Hefner

And thanks to these donors in 2024:

Jim Lara, Joseph Stadelmann, Dixon Smith, Barry Warner, Wayne Mudge, Joseph Vandenbosch, Ian Campbell, Jay Apt, John Kimmons, Derek Rowan, Michael Maya Charles, Ron Horton, Lauren McGavran, Gerald Magnoni, Amy Haig, Rod Partlo, Brent Chidsey, Mard Sasaki-Scanlon, SABRIS Aviation (Dave Dewhirst), Edmund Braly, Joseph Orlando, Charles Lloyd, Michael Morrow, Abigail Dang, Thomas Jaszewski Danny Kao, Gary Garavaglia

Pursue Mastery of Flight

Thomas P. Turner, M.S. Aviation Safety

Flight Instructor Hall of Fame Inductee

2021 Jack Eggspuehler Service Award winner

2010 National FAA Safety Team Representative of the Year

2008 FAA Central Region CFI of the Year

FLYING LESSONS is ©2024 Mastery Flight Training, Inc. For more information see www.thomaspturner.com. For reprint permission or other questions contact [email protected].