Topics this week include: > The real answer > We’ve got to do better > Hypervigilance

FLYING LESSONS uses recent mishap reports to consider what might have contributed to accidents, so you can make better decisions if you face similar circumstances. In most cases design characteristics of a specific airplane have little direct bearing on the possible causes of aircraft accidents—but knowing how your airplane’s systems respond can make the difference in your success as the scenario unfolds. So apply these FLYING LESSONS to the specific airplane you fly. Verify all technical information before applying it to your aircraft or operation, with manufacturers’ data and recommendations taking precedence. You are pilot in command and are ultimately responsible for the decisions you make.

FLYING LESSONS is an independent product of MASTERY FLIGHT TRAINING, INC.

Pursue Mastery of Flight™

This week’s LESSONS:

A Piper Navajo was conducting an aerial survey flight that lasted over five hours before the pilot began his return to home base. The big twin ran out of fuel, the pilot dead-sticked into a busy highway, and the Piper collided with cars and obstructions, breaking the fuselage apart. AVweb reports:

The FAA’s preliminary report noted the aircraft struck two vehicles before splitting in half at a busy intersection. Victoria police provided an update Thursday, confirming that three of the four people injured on the ground were treated and released from the hospital, while a fourth individual remains in stable condition. The pilot, who was the aircraft’s sole occupant, was also treated and discharged…. Before the emergency landing, the aircraft was flying a grid pattern over the San Antonio area for several hours.

While on a night approach the pilot of a Cessna 340 encountered engine problems near the end of a five-hour flight. According to preliminary reports the pressurized twin:

…sustained substantial damage. The pilot sustained serious injuries and four passengers sustained minor injuries. Prior to departure the airplane was “topped off.” The airplane departed Mission Field Airport (KLVM), Livingston, Montana. The airplane traveled nonstop, via an instrument flight rules flight plan, to its intended destination of the Muskogee-Davis Regional Airport (KMKO), Muskogee, Oklahoma.

Air traffic control cleared the airplane for a visual approach to runway 13. Shortly after, the pilot reported a loss of engine power occurred with both engines. The pilot attempted to restart both engines to no avail. During the forced landing, the right wing impacted a permanent static display on airport property, a U.S. Air Force T-33A jet trainer. The static display is located about 3350 feet to the northwest of the approach end of runway 13.

During the impact sequence, about half of the right wing of the Cessna 340A became separated, and the empennage of the U.S. Air Force T-33A became separated. The airplane came to rest upright on a flat grass field on airport property, near the static display. The pilot and the four passengers (one adult and three minor age children) were able to egress from the airplane without further incident. The airplane sustained substantial damage to the fuselage and the right wing. The wreckage was recovered from the accident site to a secure location for a future examination.

My friends at General Aviation News recently published this account of a Pipistrel Virus SW fuel exhaustion accident:

The two pilots were conducting multiple cross-country flights the day of the accident with the purpose of building flight time as part of an air carrier pilot development program. The pilots departed for the fourth leg of the day and the left seat pilot was primarily flying for this leg.

Both pilots reported that while en route they noticed the fuel level was low. Subsequently, about 15 nautical miles from the destination, the Pipistrel Virus SW’s engine lost all power. The left seat pilot reported that the right seat pilot took control of the airplane after the loss of power.

About 600 feet above ground level (AGL) the right seat pilot deployed the ballistic parachute recovery system when it became clear that they would not be able to glide to an airport. The impact with the ground near Cross City, Florida, resulted in substantial damage to the fuselage. Post-accident inspection of the fuel system showed no fuel visible in either wing tank and no fuel visible in the inline fuel filters.

How much fuel does your airplane burn? If you’re like most pilots you’ll answer with the cruise fuel flow. “My airplane burns 12 gallons per hour,” for example. But what about fuel for takeoff and climb? The airplanes I most commonly fly—various models of later Beech Bonanzas with 285 to 300 horsepower engines—burn between 12 and 14 gallons per hour in the 7000 to 9000 Mean Sea Level (MSL) range if leaned for best fuel specifics (most horsepower for unit of fuel burned). But takeoff and climb from my home airport at about 1400 MSL and I’ll go through a quarter tank of fuel—close to 10 gallons—in the time it takes to reach cruising altitude. If I stay lower, say 4000 to 6000 MSL, it takes less fuel to climb but the cruise fuel flow increases.

What is your airplane’s range? Most pilots will have an answer to that question. But range—the distance an airplane can travel—is variable based on power setting, itself a function of mixture management technique, Range is wildly dependent on winds…a factor almost completely out of our control. For a given power setting an airplane has a theoretical range in zero winds, but since that’s virtually impossible the idea of a fixed range is not really usable for flight planning.

What is your airplane’s endurance? That’s the real answer to know. An airplane will fly a certain amount of time before it runs out of fuel. That time still varies depending on fuel load at takeoff, selected power setting, altitude, time to climb, and more.

Because there are so many variables, it’s critical that you know the fuel level at takeoff, the expected fuel burn for climb and cruise fuel flow, as well as fuel required for descent, approach and even missed approach or go-around, re-climb to altitude, and cruise to and approach and landing at an alternate airport. Add to that, at a minimum, the regulatory endurance (30 minutes for day VFR under U.S. rules; 45 minimums for IFR or night VFR). I use one hour remaining as my minimum.

Further, you must monitor fuel flow in flight to confirm your planning remains valid and to detect any condition where fuel use is not meeting preplanned expectations. This includes scanning behind fuel caps and along the trailing edge of the wings for any sign of fuel leaks or overflows that are not detectable by fuel transducers and engine monitors. Fuel siphoning and venting scenarios may even cause an erroneously high fuel quantity indication in some types of aircraft.

If you think aircraft fuel gauges are “notoriously inaccurate” and “only need to read accurately when the tank is empty,” then you have not read the regulatory requirements for fuel gauge accuracy across the full range of indications. Among many other things, 14 CFR 23.2430(a)(4) requires aircraft fuel systems to “Provide the flightcrew with a means to determine the total useable fuel available….” Not just when the tanks are empty, or when they are full, but the total usable fuel available at any time. Fuel quantity gauges are inaccurate only if the aircraft owner has not maintained them properly.

It’s even more important to have a plan for managing your fuel system in flight, and to follow your plan once airborne. Fuel starvation—when there’s usable fuel on the airplane but it is not getting to the engine(s)—is more common in accident reports than fuel exhaustion, running completely out of fuel. Although it seems reasonable to assume an engine will restart immediately if a tank runs dry and the pilot switches to a tank that contains fuel, the record shows this doesn’t always work…a lot. Follow a plan, use a timer or reminder to prompt fuel tank selection, and switch tanks before the tank runs completely dry to avoid the single most common cause of engine failure accidents.

Put all the variables together and, with some notable exceptions, most light airplanes seem to have about five hours of fuel on board when filled to maximum capacity and with the engine and fuel tank system managed properly. If the total time since the last top-off has been more than four hours you probably have less than an hour’s fuel remaining. Although regulations permit taking off with as little as half an hour of fuel expected to be remaining when you land, that’s only for planning purposes and many pilots adjust their flight to land before they have only an hour of fuel remaining on board based on calculations updated as a flight progresses.

Some countries require at least the minimum fuel reserve to actually be in the tanks at the end of a flight. Burn any of your reserves and you’ve violated those justifications’ regulations.

Regardless, if you take off with full tanks and your airplane has about five hours of fuel on board, land before you reach four hours aloft…even if you have to land somewhere inconvenient, fuel up regardless of price, and then only fly a short distance to your original destination. If you depart with less than full tanks, or have a fuel tank system that provides for greater endurance, adjust that time accordingly.

Any flight planned to within an hour of the endurance resulting from fuel load at takeoff, climb, cruise, descent, approach, go-around/missed approach, climb, diversion and landing with no less than regulatory fuel reserves plus any personal minimum is a science experiment. It may turn out the way you expect, if you monitor closely and manage all the variables correctly. But it’s equally possible you’ll get a different outcome that requires landing for more fuel before you burn into that reserve.

I was an Account Executive selling aircraft insurance in AOPA’s insurance company in the mid-1990s. When taking applications for insurance we asked all the standard questions, including whether the applicant had any accident or aircraft insurance claims experience in the previous five years. But our underwriters had us ask if a pilot had ever had a fuel starvation or fuel exhaustion accident or insurance claim. Fuel mismanagement was “the unforgivable sin” that made a pilot essentially uninsurable for the rest of their life.

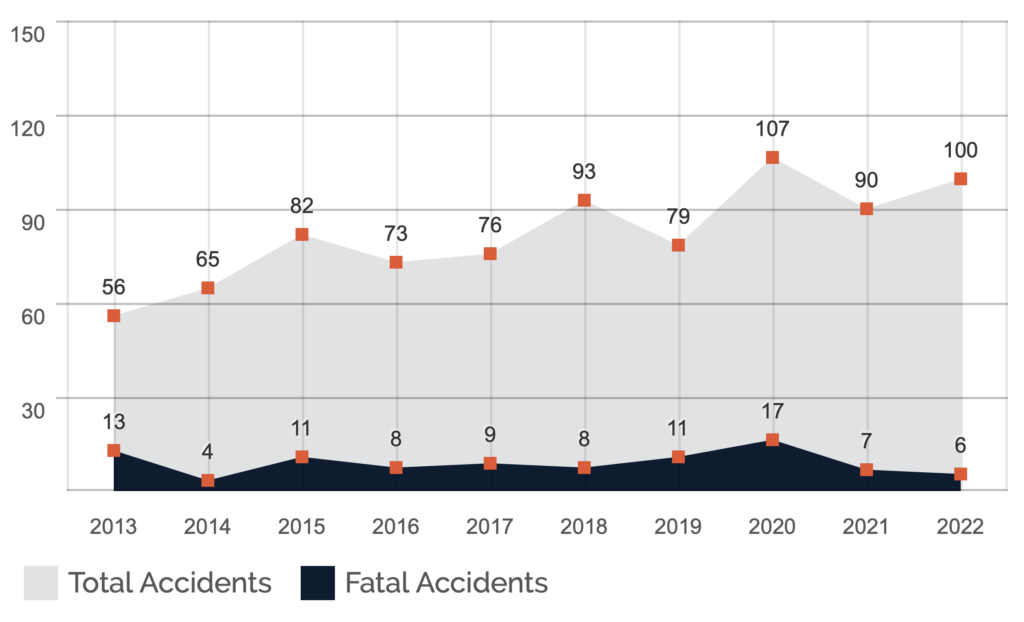

Justified, fair or not, way too many accidents result from fuel mismanagement. AOPA’s Air Safety Institute reviews of NTSB reports indicate as much as 90% of all NTSB-investigated engine failure accidents are the result of the pilot’s operation of the fuel system. And the recently released 2024 Richard G. McSpadden Report shows that the trend in fuel mismanagement accidents is showing a decade-long increase, nearly doubling over the past 10 reporting years.

Fuel-related accidents 2013-2022 (2024 McSpadden Report)

We’ve got to do better…and if we do, we can prevent the vast majority of engine failure accidents.

Questions? Comments? Supportable opinions? Let us know at [email protected].

An hour’s worth

Has what you’ve learned in FLYING LESSONS this year been worth it to you? How many hours of “dual” have you received from the weekly reports? If you’ve learned at least as much as you do in an hour of flight instruction please consider donating the amount you’d pay your flight instructor for just one hour of her/his time to help me cover the costs of hosting, delivering and improving FLYING LESSONS Weekly. If that’s more than you think it’s been worth, even $10 is greatly appreciated. Or send a check made out to Mastery Flight Training, Inc. at 247 Tiffany Street, Rose Hill, Kansas USA 67133.

Thank you to my monthly supporters, listed below, to all who have contributed through the year (also listed), and all who will help now and in 2025. I appreciate your support that helps us all become safer and more proficient pilots.

Debrief

Readers write about previous LESSONS

New reader Brad Wolanski, who regularly flies a Piper Seneca between Lakeland, Florida and the Bahamas, has “recently created a type specific group for the Seneca because none previously existed” at www.pa34owners.org and https://forums.pa34owners.com. Brad “hope[s] to include topics and stimulate discussion about flying the Seneca safely. And in particular, of course, responding to its emergencies.” Seneca pilots, instructors and enthusiasts, check it out.

Frequent Debriefer John Scherer writes about the LESSONS I learned from attending the 2024 Bombardier Safety Standdown:

I’m also a big fan of Tony Kern. I love [his quote] “hypervigilance is a required competency in the cockpit.” Let me paint a picture in the C-5 [Galaxy] about what I thought about on each takeoff. And I think about similar things when taking off in our P35 Bonanza.

The C-5 Galaxy. I loved flying that airplane for more than 2,300 hours. Hypervigilence was super critical on takeoff. At heavy weights, the C-5 was a ground loving airplane. I’ve been on takeoff rolls that took one minute and 15 seconds. Time your next takeoff on a B-737 and it’s about 35 seconds. A heavyweight B-777 is about 44-45 seconds.

At 700,000 pounds, the C-5 would have a rotate speed of about 145 KIAS [knots indicated airspeed]. Ground roll would be about 7,000 feet. I always asked the flight engineer for the takeoff roll number, so I knew where we would be lifting off. I also asked for a refusal speed (fastest speed you could accelerate to and still stop on the runway). That gave me a reference point if something catastrophic happened after “rotate” [but] before liftoff. On heavyweight takeoffs, we calculated a check speed (for example 120 knots at 55 seconds). We had to make that within 3 knots or reject the takeoff. Know your takeoff roll in the Bonanza and have a check speed. I use 70% of rotate speed at 1/2 of ground roll as my check in the Bonanza ON EVERY TAKEOFF.

The “70/50 rule,” that is, the airplane should be at 70% of its computed liftoff speed at 50% of its computed takeoff ground roll under current conditions, is a common way of confirming whether air airplane is accelerating properly or the pilot should immediately perform a rejected takeoff (RTO).

John continues:

The C-5 had other considerations. For example at 700,000 pounds, if we lost an engine the flight engineer would have to immediately start dumping fuel to help 3 engine climb. I always asked what the 2 engine ceiling was for that day’s conditions. It was usually below sea level, so dumping was necessary. The C-5 could dump prodigious pounds of fuel per minute if necessary. A C-5 at Dover AFB ran into about 100 snow geese as they lifted off. The geese took out two engines. The aircraft commander dumped 60,000 pounds of fuel as he did an emergency return to an ILS at Dover to weather below minimums. He got a Distinguished Flying Cross for that flight.

So, when I pushed the throttles (I never liked “thrust levers”) forward, I was hypervigilant about the takeoff ground roll, where I would rotate, what my check speed was. And I made sure the flaps were set at 40% and the leading edge slats were extended. A no flap takeoff was DEADLY. And we checked the flight controls twice before takeoff roll.

Rolling down the runway, I’m making sure I’m on the centerline on the correct runway (which I had checked on the lineup checklist). Also, I made sure if we had an EPR (exhaust pressure ration) engine gage, that the N1’s were where they were supposed to be. Remember Air Florida in 1982 when the EPR looked okay, but the N1’s were way low. And I’m watching the fuel flows and airspeed closely.

N1 is the rotational speed of a jet engine’s low-pressure spool, which is made up of the fan, low-pressure compressor, and low-pressure turbine. N1 is usually displayed as a percentage of the engine’s maximum rotational speed (RPM). N1 is a primary indicator of engine thrust on many jet engines. John continues further:

When the pilot monitoring called GO, we were committed except a catastrophic failure. If we rejected above GO, the brakes would be SUPER hot. The passengers would have to go out the slides, and someone would be hurt sliding down the slides from the upper deck.

Once airborne, it was time to fly and get the beast accelerated up to climb speed as soon as possible. Min[imum] speed clean at that weight was 205 KIAS. We accelerated to that as soon as possible as the flaps and slats came up. Then I could relax a little bit and be hypervigilant about the weather, etc. as we climbed to cruise, which could take 30 minutes in the summer.

That’s what hypervigilance sounds like in the C-5. And we should be thinking about many things on each of our takeoffs [in any airplane].

Thanks for a great peek into the world of super-heavy airplane operations, John, and how that experience applies to flying light airplanes.

Reader Vas Ketavarapu adds to last week’s Debrief on the availability of Minimum Vector Altitude (MVA) and Minimum IFR Altitude (MIA) information, useful in making instrument departures from nontowered airports and also when planning to depart under Visual Flight Rules and “pick up” an IFR clearance in the air:

On the topic of MVA and MIA, if you are not already aware of it, you can download KML files for MVAs and MIAs that can then be imported into Foreflight as a custom layer from the following link: https://github.com/dark/faa-mva-kml. The image shows what it looks like in Foreflight.

There are multiple ways to import them from that site but the easiest seems to be to go to the content pack directory and then download either the MIA or MVA content pack for your area (you can look at the main FAA site to get the acronym for your area – e.g. NCT is Northern California) to your iPad/iPhone and then share it or open it in Foreflight at which point the file will get imported as a custom content pack.

Great information, Vas. Thank you.

More to say? Let us learn from you, at [email protected]

Share safer skies. Forward FLYING LESSONS to a friend.

Please help cover the ongoing costs of providing FLYING LESSONS through this secure PayPal donations link. Or send a check made out to Mastery Flight Training, Inc. at 247 Tiffany Street, Rose Hill, Kansas USA 67133. Thank you, generous supporters.

Thank you to our regular monthly financial contributors:

Steven Bernstein, Montclair, NJ. Robert Carhart, Jr., Odentown, MD. Greg Cohen, Gaithersburg, MD. John Collins, Martinsburg, WV. Dan Drew. Rob Finfrock, Rio Rancho, NM. Norman Gallagher. Bill Griffith, Indianapolis, IN. Steven Hefner, Corinth, MS; Ellen Herr, Ft Myers, FL. Erik Hoel, Redlands, CA. Ron Horton. David Karalunas, Anchorage, AK. Steve Kelly, Appleton, WI. Karl Kleiderer. Greg Long, Johnston, IA. Rick Lugash, Los Angeles, CA. Richard McCraw, Hinesburg, VT. David Ovad, Resiertown, MD. Steven Oxholm, Portsmouth, NH. Brian Schiff, Keller, TX. Paul Sergeant, Allen, TX. Paul Uhlig, Wichita, KS. Richard Whitney, Warrenton, VA. Jim Preston, Alexandria, VA. Johannes Ascherl, Munich, Germany. Bruce Dickerson, Asheville, NC. Edmund Braly, Norman, OK. Steven Hefner. Lorne Sheren, New Vernon, NJ. “The Proficient Pilot,” Keller, TX. Ed Stack, Prospect Heights, IL. Kynan Sturgiss, Hereford, TX

NEW THIS WEEK: Bluegrass Rental Properties, LLC, London, KY.

And thanks to these donors in 2024:

Jim Lara, Joseph Stadelmann, Dixon Smith, Barry Warner, Wayne Mudge, Joseph Vandenbosch, Ian Campbell, Jay Apt, John Kimmons, Derek Rowan, Michael Maya Charles, Ron Horton, Lauren McGavran, Gerald Magnoni, Amy Haig, Rod Partlo, Brent Chidsey, Mard Sasaki-Scanlon, SABRIS Aviation (Dave Dewhirst), Edmund Braly, Joseph Orlando, Charles Lloyd, Michael Morrow, Abigail Dang, Thomas Jaszewski Danny Kao, Gary Garavaglia, Brian Larky, Glenn Yeldezian, David Yost, Charles Waldrop, Robert Lough. Gilbert Buettner. Panatech (Henry Fiorientini). Dale Bleakney. Mark Kolesar. John Winter. Donald Bowles. David Peterson. Bill Abbatt. Bruce Jacobsen. Denny Southard, Wayne Cloburn, Ross Ditlove. “Bonanza User,” Tad Santino, Steven Scharff, Kim Caldwell, Tom Carr, Michael Smith. David Kenny. Lorne Sheren. Stu Spindel. Martin Sacks. Arthur Utay.

NEW THIS WEEK: John Whitehead. Brenda Hanson. Mark Sanz. Tim Schryer. Bill Farrell. Todd LeClair. Craig Simmons. Lawrence Peck. Howard Page. Jeffery Scherer. John Kinyon. Lawrence Copp. Joseph Stadelmann.

Pursue Mastery of Flight(TM)

Thomas P. Turner, M.S. Aviation Safety

Flight Instructor Hall of Fame Inductee

2021 Jack Eggspuehler Service Award winner

2010 National FAA Safety Team Representative of the Year

2008 FAA Central Region CFI of the Year

FLYING LESSONS is ©2024 Mastery Flight Training, Inc. For more information see www.thomaspturner.com. For reprint permission or other questions contact [email protected].