FLYING LESSONS uses recent mishap reports to consider what might have contributed to accidents, so you can make better decisions if you face similar circumstances. In most cases design characteristics of a specific airplane have little direct bearing on the possible causes of aircraft accidents—but knowing how your airplane’s systems respond can make the difference in your success as the scenario unfolds. So apply these FLYING LESSONS to the specific airplane you fly. Verify all technical information before applying it to your aircraft or operation, with manufacturers’ data and recommendations taking precedence. You are pilot in command and are ultimately responsible for the decisions you make.

FLYING LESSONS is an independent product of MASTERY FLIGHT TRAINING, INC.

Pursue Mastery of Flight™

This week’s LESSONS:

All four aboard a Beech F33A Bonanza died this week when, according to witnesses and preliminary investigative information, its “left wing struck a hay bale and [the aircraft] crashed into trees” during an attempted takeoff from Sundance Airport at Oklahoma City, Oklahoma. Local sources tell me the four-seat airplane was fully fueled and the ambient temperature was 103° Fahrenheit (40° Celsius) for takeoff from the roughly 5000-foot (1500 meter) paved runway.

We don’t yet know if the failure to clear obstacles was the result of airplane weight or loading, a pilot technique issue, a partial or total power loss or some other factor. It may even have been a directional control issue, with the hay bale off the side of the runway—we have no firm data, not yet. The airplane load and ambient conditions make one of the LESSONS to learn from this preliminary information, however, the effect of weight and temperature on takeoff performance.

Weight

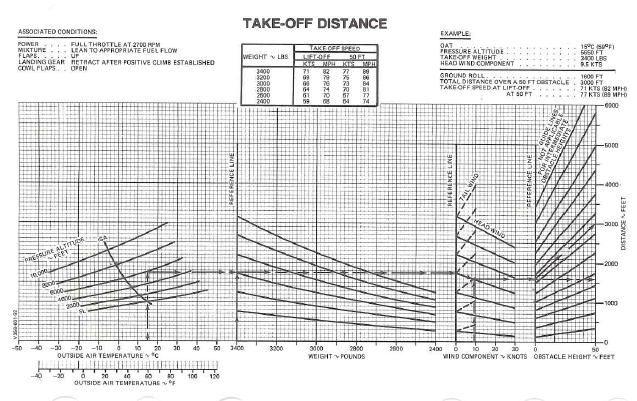

Let’s assume an airplane of the same type involved in this week’s tragedy was loaded right at its maximum takeoff weight of 3400 pounds (1542 kilograms), and that its weight was distributed so that the airplane was within the approved loading envelope. Under conditions at the time:

- Temperature 40°C

- Field elevation 1193 feet (364 meters)

- Winds calm (because we don’t yet know otherwise)

…the density altitude comes to about 4300 feet (1310 meters). Using Pilot’s Operating Handbook takeoff speeds and technique this results in roughly 1300 foot/400 meter takeoff ground roll and 2500 foot/760 meter distance from the beginning of the takeoff roll to a point 50 feet/15 meters above ground level.

What if instead of loading the airplane full of fuel (37 US gallons usable, 444 pounds/200 kilograms) the fuel load was reduced by 100 pounds/45 kilograms? Under the same environmental conditions takeoff distance would be 1200 feet/366 meters and the 50-foot distance would be 2200 feet/670 meters. This isn’t a big difference, but it would make it much less likely to hit a hay bale off the end of the runway.

Take off with half-full tanks and, at 220 pounds/100 kilograms below maximum gross weight the takeoff ground roll would be 1100 feet/335 meters and 50-foot distance would be 1900 feet/580 meters. Savvy F33A pilots may know that this may well be impossible given center of gravity limits, but that’s outside the scope of this discussion.

The point is that takeoff ground roll and obstacle clearance distances are noticeably improved with even fairly small reductions in airplane weight. Now compare even the maximum gross weight figures with the available runway distance and the accident airplane should have been well above hay-bale height at only about halfway down the runway. Reducing takeoff weight is a choice you can make to give yourself a great margin under otherwise adverse conditions like density altitude.

Temperature

Say instead you choose to load the airplane up to maximum. You have options with temperature as well. The accident airplane departed in late morning, not at the maximum temperature for the day but reportedly when it was over 100 degrees Fahrenheit (40 Celsius) out. That was about the temperature here near Wichita the afternoon I wrote this, and it was about 70°F/21°C as I drove in to work that morning.

If instead of trying a near-noon departure you get the passengers out of bed and take off in the cooler air around 8 am, you’d find the maximum-weight ground roll to be even better, about 1100 feet/335 meters and the 50-foot distance around 1900 feet/580 meters…the same effect as reducing half the fuel weight! Timing your flight for a cooler time of day is another choice you can make to improve takeoff margins.

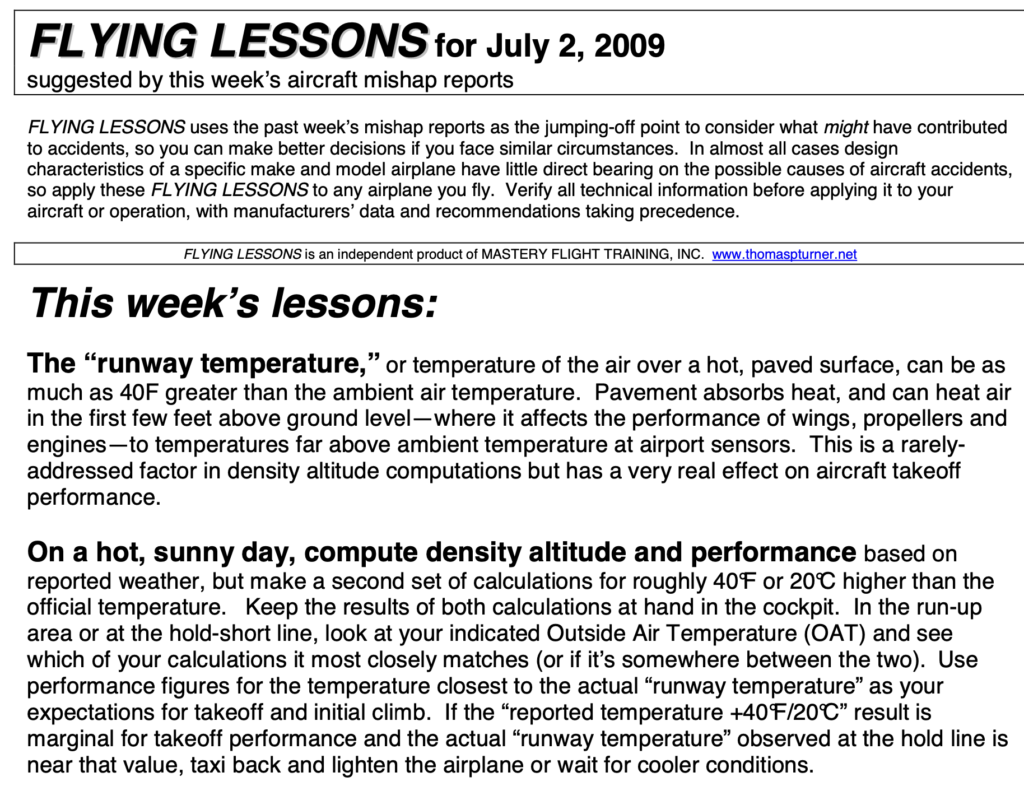

Ever walked on hot pavement? A runway absorbs heat and transfers that heat to the air above it. The hotter the ambient temperature the hotter the air will be in the first few feet/meters above a paved runway—in the space engines are trying to create power and winds are trying to generate lift. Take a look at this except from a 2009 FLYING LESSONS Weekly report that covers (briefly) the concept of runway temperature. All the more reason to plan your departure to take advantage of cooler air if you need to depart at or near maximum weight.

What if the airplane has a legally approved increase in maximum gross weight? Most such approvals give only general guidance on the negative performance impact of operating at weights above that originally approved for the airplane. Use that additional capability very cautiously, and only in cooler weather at low altitude airports at least until you have extensive personal experience in that airplane at those weights to be able to predict performance under more hazardous conditions.

What if you use some technique and/or airspeeds different from that recommended by the manufacturer in the POH? Use a different technique and you’ll get different performance, likely worse, with no way to predict for certain unless you have substantial personal experience using your alternate technique under similar conditions. You might build up to that knowledge using long runways under more benign conditions. But don’t commit yourself to an experiment under real-world conditions until you know from experience your technique will work.

What if the center of gravity is within the approved envelope, but near either the extreme forward or rearward edge of the envelope? Forward CG is a stability enhancing condition that increases breakout force (i.e., airflow and/or control movement) to alter airplane pitch, as a result increasing ground roll and decreasing initial climb performance. Rearward CG is a stability reducing condition that improves initial takeoff and climb performance, but which may make the airplane difficult to control precisely.

What if the airplane is loaded forward or rearward out of limits? Don’t do it. Enough said.

What if it’s within limits, but because of fuel burn in the airplane type will go out of limits well before you run out of gas? In that case you’ll need to do a lot more flight planning, to determine your total endurance—including diversion to an alternate if needed—with the airplane still within the center of gravity envelope, and precisely manage your flight to be on the ground before the airplane exceeds limits.

Our typical instructional method often does pilots a disservice. Instructors rarely train pilots near the edges of the loading and balance envelopes. We rarely train when the temperature exceeds 100°F/40°C. We almost never have students plan and conduct flights requiring a full fuel load at takeoff, but we almost always have students depart with a full fuel load—so they don’t learn to make fuel vs. performance tradeoffs. Many pilots complete training, even for advanced certificates, without learning how to order fuel away from home base, let alone use a self-service fueling station. As an instructor I realize the risks in deviating from this norm, but I think we’d all benefit from a little exposure to figuring out the tradeoffs and making decisions that don’t always result in departing with full fuel or at maximum takeoff weight.

What if you reduce airplane weight and take off in cooler conditions? That’s the LESSON I draw from the incomplete information in the tragic case that starts this week’s discussion. You have choices that can dramatically reduce risk and increase your margin of safety—and you should make them.

Questions? Comments? Supportable opinions? Let us know at [email protected].

Debrief

Readers write about recent FLYING LESSONS:

Reader Mike Dolan responds to last week’s LESSONS on decision-making related to mechanical failures discovered away from home:

Responding to the problems enroute, I would go to extremes not to have my airplane worked on away from home. Examples:

Once during a long cross country flight a vacuum pump failed so I put the plane in a local shop. Not only was it more expensive, I didn’t get to choose the replacement I would have preferred.

Two other failures occurred much later away from home that required a decision. Once the transponder and another time the next vacuum pump failed. Each time I contacted my IA/A&P to discuss the issue. These decisions are not to be taken lightly. For the transponder, I returned home below 10,000 feet without it. Slower return home at that altitude, but a return nonetheless. For the vacuum pump, which takes out the flight instruments and therefore autopilot, I hand flew the airplane home. Instrument back-up in my case is a Garmin aera 660 with its flight instrument screen. Aren’t modern gadgets wonderful?

During these flights I marveled at how every last doggone thing in the airplane must work.

Once even the cigar lighter socket was fixed enroute. Any drive train failure; engine, propeller, generator, fuel pump, magneto, plugs or wires must be fixed before flight – away from home if necessary. Any avionics failure must be evaluated before return. I used a cell phone once for communication during Comm failure. It worked.

So I guess flight planning for each trip should include alternate transportation should a problem arise. It has always included alternate destinations.

Great observations, Mike. Thank you.

Reader Wendell Todd adds:

Last weekend in the hangar, I planned to lubricate the flap limit roller switches as I do between annual inspections. On lowering the flaps to gain access to the switches, there was a loud bang in the inboard aft portion of the right wing. The loud bank occurred at the beginning of the flap extension, which otherwise proceeded normally. Subsequent retraction was normal.

Monday morning I contacted the shop that has done my maintenance for many years, and was advised to bring the plane, weather permitting. On contemplation, I was reluctant to fly the airplane. So, I requested the local shop to check. To our relief, the problem proved to be simply insufficient lubrication of the bolt where the rod from the flap actuator connects to the flap. The rod was binding to one side of the bracket.

This is another example of the adage: Better to be on the ground wishing you were flying, than flying wishing you were on the ground.

Thank you, Wendell.

More to say? Let us learn from you, at [email protected]

Share safer skies. Forward FLYING LESSONS to a friend.

Please help cover the ongoing costs of providing FLYING LESSONS through this secure PayPal donations link. Or send a check made out to Mastery Flight Training, Inc. at 247 Tiffany Street, Rose Hill, Kansas USA 67133. Thank you, generous supporters.

Thank you to our regular monthly financial contributors:

Steven Bernstein, Montclair, NJ. Robert Carhart, Jr., Odentown, MD. Randy Carmichael, Kissimmee, FL. Greg Cohen, Gaithersburg, MD. John Collins, Martinsburg, WV. Paul Damiano, Port Orange, FL. Dan Drew. Rob Finfrock, Rio Rancho, NM. Norman Gallagher. Bill Griffith, Indianapolis, IN. Steven Hefner, Corinth, MS; Ellen Herr, Ft Myers, FL. Erik Hoel, Redlands, CA. Ron Horton. Robert Hoffman, Sanders, KY. David Karalunas, Anchorage, AK. Steve Kelly, Appleton, WI. Karl Kleiderer. Greg Long, Johnston, IA. Rick Lugash, Los Angeles, CA. Richard McCraw, Hinesburg, VT. David Ovad, Resiertown, MD. Steven Oxholm, Portsmouth, NH. Brian Schiff, Keller, TX. Paul Sergeant, Allen, TX. Ed Stack, Prospect Heights, IL; Paul Uhlig, Wichita, KS. Richard Whitney, Warrenton, VA. Jim Preston, Alexandria, VA. Johannes Ascherl, Munich, Germany. Bruce Dickerson, Asheville, NC. Edmund Braly, Norman, OK. Steven Hefner. Lorne Sheren, New Vernon, NJ

And thanks to these donors in 2024:

Jim Lara, Joseph Stadelmann, Dixon Smith, Barry Warner, Wayne Mudge, Joseph Vandenbosch, Ian Campbell, Jay Apt, John Kimmons, Derek Rowan, Michael Maya Charles, Ron Horton, Lauren McGavran, Gerald Magnoni, Amy Haig, Rod Partlo, Brent Chidsey, Mard Sasaki-Scanlon, SABRIS Aviation (Dave Dewhirst), Edmund Braly, Joseph Orlando, Charles Lloyd, Michael Morrow, Abigail Dang, Thomas Jaszewski Danny Kao, Gary Garavaglia, Brian Larky, Glenn Yeldezian, David Yost, Charles Waldrop, Robert Lough. Gilbert Buettner. Panatech (Henry Fiorientini). Dale Bleakney. Mark Kolesar. John Winter. Donald Bowles. David Peterson

Pursue Mastery of Flight

Thomas P. Turner, M.S. Aviation Safety

Flight Instructor Hall of Fame Inductee

2021 Jack Eggspuehler Service Award winner

2010 National FAA Safety Team Representative of the Year

2008 FAA Central Region CFI of the Year

FLYING LESSONS is ©2024 Mastery Flight Training, Inc. For more information see www.thomaspturner.com. For reprint permission or other questions contact [email protected].